By Guy Nelson, P.E., S.E., and Megan Nicolaisen, Valmont Industries, Inc.

How do you know it’s spring in Michigan? Seeing the road change from white to brown; feeling the pavement change from smooth to bumpy and back again; witnessing a family of deer soaking up the sun near a drainage ditch full of snow and water…..and your peaceful drive coming to a stop for a bridge closed to traffic.

This is the experience you’ll have driving through Midland County, Michigan in the early spring months. Located nearest to Saginaw, Midland is a typical rural county in the United States. And like many of them, Midland’s rural county government agency is responsible for an increasing inventory of deteriorated bridges with a decreasing supply of funding.

Faced with the growing dilemma of replacing bridges with reduced funding, some counties have found increased efficiencies through manufacturing and constructing multiple bridges in one contract, a process known as “bundling.” Bridge bundling saves time and costs by eliminating the need for multiple contracts. The process involves pre-ordering multiple bridges and making these prefabricated bridge superstructures available for later installation by the county’s own labor force.

The Midland County Road Commission and its structural consultant, OHM Advisors, recognized the benefits of bundling when searching for an economical method to replace two structurally deficient bridges—the Orr Road Bridge over Weaks Drain and the Grey Road Bridge over Bullock Creek. To get the “most bang for the buck,” the Midland County Road Commission combined multiple innovative cost-cutting measures:

- Bundling the two bridges into a single package,

- Pre-ordering the bridge superstructures to be manufactured at the same time,

- Incorporating Geosynthetic Reinforced Soil (GRS) abutments, and

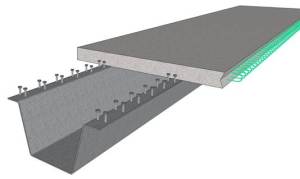

- Selecting the Con-Struct™ Prefabricated Bridge System (now known as the Valmont® Structures Con-Struct™ Prefabricated Bridge System), a press-brake-formed steel tub girder system that consists of a precast concrete deck on galvanized steel tub girders. This Accelerated Bridge Construction (ABC) product can be installed quickly and has a very long service life.

Once the bridge bunding process was set in place, the project was ready to move ahead.

Project Timeline

- July 2018 – OHM Advisors releases a single project for bid. The bid requires materials for both bridges to be delivered by spring 2019.

- August 2018 – Valmont® Structures Con-Struct™ Prefabricated Bridge System is awarded the project and begins the design and shop drawing process.

- September 2018 – The design and drawings are reviewed and approved by OHM Advisors.

- September 2018 – Valmont Structures begins fabrication of the steel press-brake-formed tub girders (PBFTGs).

- December 2018 – The fabrication and galvanization of all 12 PBFTGs are completed.

- January 2019 – The girders are shipped to ADL Systems, a precast concrete producer.

- April 2018/2019 – The precast concrete deck is manufactured. ADL completes the process and stockpiles the 12 bridge tub girder units until Midland County Road Commission is ready to install them.

- May 2019 – An extremely wet spring and summer prevents the use of GRS Abutments for the Orr Road Bridge. If using a contractor and a traditional method of bridge construction, this situation could have created extra costs for the owner with the need for dewatering to deal with high stream water levels; or, due to an extended construction schedule, the need to use heating and housing for pouring concrete in the cold winter months.

- August 2019 – The Midland County Road Commission takes delivery of 6 Valmont Con-Struct™ prefabricated bridge units for installation atop the county-installed GRS abutments for the Orr Road Bridge.

Installation of the Orr Road Bridge was completed by the end of August 2019. The bridge deck joints were then filled with a durable, high-strength polymer concrete product known as Transpo T-17. After Midland County Road Commission installed the bridge rail, the Orr Road Bridge opened to traffic in October 2019.

For the next project, the Grey Road Bridge, the additional 6 Valmont Con-Struct™ prefabricated bridge units were then delivered to the Midland County Road Commission. They are awaiting installation in 2020, whenever spring in Michigan finally decides to show up and the county’s labor force has completed its snow plowing duties.

The innovative bridge bundling concept is capturing the attention of county transportation officials nationwide. As the U.S. bridge inventory continues to age, faster and more efficient bridge replacement techniques and cost-saving measures like bridge bundling will become more widespread. For additional information on these projects, visit valmontstructures.com/bridges.

The new Orr Road Bridge in Midland County, Michigan

cold-bent structural steel plate. A

cold-bent structural steel plate. A

bridge in place – the first of its kind in the state, with results that are attracting attention nationwide from county engineers; federal, state and local transportation officials; and bridge owners.

bridge in place – the first of its kind in the state, with results that are attracting attention nationwide from county engineers; federal, state and local transportation officials; and bridge owners. it was an ideal structure for the design challenges of this particular area, which has steep ravines and low-lying areas. The stream fills up and drains quickly after stormy weather, transporting large debris such as root balls and tree limbs. Other design options would have allowed the debris to collect underneath the bridge and cause damage. But with the smooth tub girders of the new bridge, debris easily flows under it.

it was an ideal structure for the design challenges of this particular area, which has steep ravines and low-lying areas. The stream fills up and drains quickly after stormy weather, transporting large debris such as root balls and tree limbs. Other design options would have allowed the debris to collect underneath the bridge and cause damage. But with the smooth tub girders of the new bridge, debris easily flows under it.

presentations on the economics of short span bridge design to county engineers, state Department of Transportation (DOT) engineers and bridge owners. Over the years, he has received numerous questions about Life Service and Life Cycle Costs, especially concerning steel and concrete girder bridges. His answers were always anecdotal, as research didn’t exist―until now.With a keen interest in finding answers to these persistent questions, Dr. Barker took a sabbatical from the university to conduct his own research. He started with a comprehensive inventory of bridges and consideration of initial costs and installation dates, maintenance costs and timing, and end-of-service dates. After considering the availability of historical data, he narrowed the scope of research to include initial costs, future costs, and service lives of 1,186 typical steel and concrete state bridges in Pennsylvania built between 1960 and 2010.

presentations on the economics of short span bridge design to county engineers, state Department of Transportation (DOT) engineers and bridge owners. Over the years, he has received numerous questions about Life Service and Life Cycle Costs, especially concerning steel and concrete girder bridges. His answers were always anecdotal, as research didn’t exist―until now.With a keen interest in finding answers to these persistent questions, Dr. Barker took a sabbatical from the university to conduct his own research. He started with a comprehensive inventory of bridges and consideration of initial costs and installation dates, maintenance costs and timing, and end-of-service dates. After considering the availability of historical data, he narrowed the scope of research to include initial costs, future costs, and service lives of 1,186 typical steel and concrete state bridges in Pennsylvania built between 1960 and 2010.

Buchanan County (Iowa) Engineer Brian Keierleber, P.E. and others to construct the first bridge designed with eSPAN140. Opened to service in 2013, the

Buchanan County (Iowa) Engineer Brian Keierleber, P.E. and others to construct the first bridge designed with eSPAN140. Opened to service in 2013, the